CAD/CAM/CAE Courses

- Mechanical CADD

- Advanced Injection Mold Design

- Wirecut Training

- Architectural CADD

- Electrical CADD

- Civil CADD

- Advanced Auto Domain Training

- Plastic Technology

- Project Management

CAD/CAM/CAE Training

Course Enquiry

Franchise Enquiry

Amit Goswami

Call Us: +91 88 0285 0707

Center Head

Plastic Technology

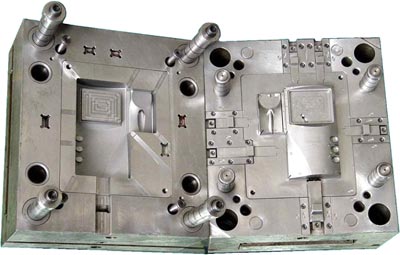

- Introduction to mould.

- Types of Mould.

- Layout of mould base using free-hand sketch.

- Layout of mould base using AutoCAD & Pr/ENGINEER.

- Runner & Gate balancing.

- Core-Cavity extraction in Pro/ENGINEER.

- Types of runner & gate.

- Ejection techniques.

- Knowledge of Instruments & GD&T.

- Types of Mechanisms used in mould.

- Basic concept of Parting Line selection

Pro/MOLD

Module 1 – Introduction to the Pro/ENGINEER Basic Mold Process

- Pro/ENGINEER Basic Mold Process

Module 2 – Design Model Preparation

- Understanding Mold Theory

- Preparing Design Models for the Mold Process

- Creating Rib Features

- Creating Draft Features

- Creating Basic Split Drafts

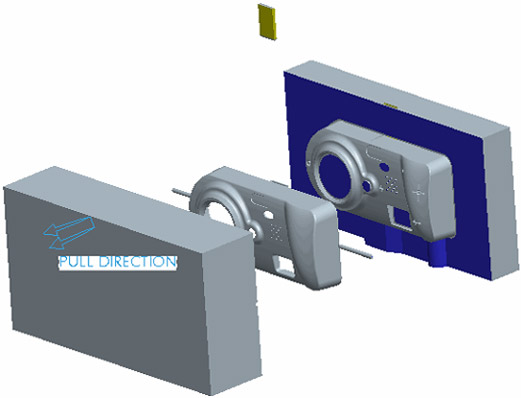

- Analyzing Draft Hinges and Pull Direction

- Creating Drafts Split at Sketch

- Creating Drafts Split at Curve

- Creating Drafts Split at Surface

Module 3 – Design Model Analysis

- Analyzing Design Models Theory

- Performing a Draft Check

- Understanding Mold Analysis Settings

- Performing a Thickness Check

Module 4 – Mold Models

- Creating New Mold Models

- Analyzing Model Accuracy

- Creating the Reference Model

- Redefining the Reference Model

- Analyzing Reference Model Orientation

- Analyzing Mold Cavity Layout

- Analyzing Variable Mold Cavity Layout

- Analyzing Mold Cavity Layout Orientation

- Calculating Projected Area

Module 5 – Shrinkage

- Understanding Shrinkage

- Applying Shrinkage by Scale

- Applying Shrinkage by Dimension

Module 6 – Workpieces

- Creating Style States using the View Manager

- Creating a Workpiece Automatically

- Creating a Custom Automatic Workpiece

- Creating and Assembling a Workpiece Manually

- Reclassifying and Removing Mold Model Components

Module 7 – Mold Volume Creation

- Surfacing Terms

- Understanding Mold Volumes

- Sketching Mold Volumes

- Creating Sliders using Boundary Quilts

- Sketching Slider Mold Volumes

- Creating a Reference Part Cutout

- Sketching Lifter Mold Volumes

- Replacing Surfaces and Trimming to Geometry

- Sketching Insert Mold Volumes

Module 8 – Parting Line and Parting Surface Creation

- Understanding Parting Lines and Parting Surfaces

- Creating an Automatic Parting Line using Silhouette Curves

- Analyzing Silhouette Curve Options: Slides

- Analyzing Silhouette Curve Options: Loop Selection

- Creating a Skirt Surface

- Analyzing Skirt Surface Options: Extend Curves

- Analyzing Skirt Surface Options: Tangent Conditions

- Analyzing Skirt Surface Options: Extension Directions

- Analyzing Skirt Surface Options: ShutOff Extension

- Analyzing Surface Editing and Manipulation Tools

- Merging Surfaces

- Creating Saddle Shutoff Surfaces

- Creating a Parting Surface Manually

Module 9 – Splitting Mold Volumes

- Splitting the Workpiece

- Splitting Mold Volumes

- Splitting Volumes using Multiple Parting Surfaces

- Blanking and Unblanking Mold Items

- Analyzing Split Classification

Module 10 – Mold Component Extraction

- Extracting Mold Components from Volumes

- Applying Start Models to Mold Components

Module 11 – Mold Features Creation

- Creating Waterline Circuits

- Analyzing Waterline End Conditions

- Performing a Waterlines Check

- Creating Sprues and Runners

- Creating Ejector Pin Clearance Holes

- Creating UDFs

- Placing UDFs

Module 12 – Filling and Opening the Mold

- Creating a Molding

- Opening the Mold

- Draft Checking a Mold Opening Step

- Interference Checking a Mold Opening Step

- Viewing Mold Information