- Mechanical CADD

- Advanced Injection Mold Design

- Wirecut Training

- Architectural CADD

- Electrical CADD

- Civil CADD

- Advanced Auto Domain Training

- Plastic Technology

- Project Management

Amit Goswami

Call Us: +91 88 0285 0707

Center Head

Advanced Auto Domain Training

Fundamentals of Vehicle Design and Packaging

Automotive Chassis Training – NX-Unigraphics

Automotive Essentials Training– NX-Unigraphics

Automotive Interior Trim Training– NX-Unigraphics

Automotive Powertrain Training– NX-Unigraphics

NX Automotive Structures Training– NX-Unigraphics

Fundamentals of Vehicle Design and Packaging

Course Content

History

- Introduction

- First Car, Front Engine, Alternative Propulsion

- Mass Production, Unibody, Art & Science

- Aero, People’s Car, 4X4

- Truck, Design With Passion, Passenger Priority

- Mid-Engine, British Roadster, Luxury SUV

- Downforce, Hatchback, Minivan

- Micro, XX LRG, Neighborhood Electric Vehicles

Getting Started

- Introduction

- Process Advanced and Production

- Systems Segments and Anatomy

- Step By Step Process One Through Four

- Step By Step Process Five Through Ten

- Designing With Sections Main

- Designing With Sections Rear View

- Grids, Ground Planes, Vehicle Attitudes, Tire Size, And Ride Height

- Hardpoints And Package Drawing

Functions & Segments

- Introduction

- Factors That Drive Functional Objectives and Applying Them to Architecture

- Vehicle Positioning

- Micro, Economy, Luxury, & Specialty Cars

- Minivans, SUV’s, Pickup Trucks, & Commercial Vans

Package Ideation

- Introduction

- Word Picture, Sketches, Ideation, and Unorthodox Thinking

Size & Proportion

- Introduction

- Size and Proportion, Key Dimensions, and Product Benchmarking

Occupant Packaging

- Introduction

- Manikin Anatomy and Occupant Environment Set-Up

Interiors & Cargo

- Introduction

- Instrument Panel & Control Set-Up

- Interior Volumes and Cargo

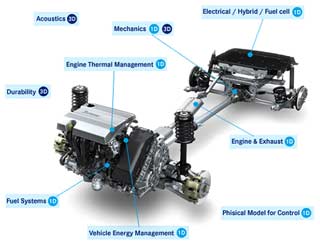

Powertrain

- Introduction

- Powertrain Anatomy & Selection

- Power, Engine Size, & Location

- Powertrain Layouts 1-4

- Powertrain Layouts 5-8 & Fuel Storage

Wheels & Tires

- Introduction

- Tire Sidewall, Wheel Flange, & Brakes

- Tire Envelopes, Spare, Tire Coverage, Tire-To-Body, & Steering

Suspension & Chassis

- Introduction

- Suspension Overview

- Suspension Systems

Bodies

- Introduction

- Load Paths & Types of Body Structures

- Sections, Design for Impact, Safety, & Material Application

- Body Closures, Side Aperture Design, & Cutlines

- Foot Swing, Door & Aperture Design, & Dropping Glass

- Windshield Aperture Design, Backlight, Aerodynamics, & Lighting

- Bumper Design, Ground Clearance, Glazing, & License Plates

Automotive Chassis Training- NX-Unigraphics

Course Contents

- Automotive Chassis Diploma Introduction

- Automotive Chassis Overview

Design Principles (AC)

- Design Principles Introduction

- Design Planning Stage

- Starting the CAD Model (AC)

- Modeling Best Practices (AC)

- Creation Methodology (AC)

- Settings and Rule (AC)

Design Modeling Techniques (AC)

- Design Modeling Techniques Introduction (AC)

- Modeling Creation Methods (AC)

- Clean Edge Modeling Technique (AC)

- Clean Edge Approach Bracket

- Shaping the Part (AC)

- Frame Rail Rough Shape

Draft (AC)

- Draft Introduction

- Part Draft using Taper

- Taper

- Taper Creation – Faces

- Taper Creation – From Edges

- Taper Creation – Tangent to Faces

- Taper Creation – Split Line

- Taper Editing

Parting Line Development (AC)

- Parting Lines Introduction

- Parting Lines Overview (PC)

- Project

- Projected Points and Curves Editing

- Intersect

- Intersection Curve Editing

- Section

- Subdivide Face

Thin – Walled Bodies (AC)

- Thin-walled Bodies Introduction (AC)

- Thin-walled Bodies (AC)

- Hollow

- Hollow Creation – Face

- Extract

- Extracting Faces

- Extracting a Region

- Thicken Sheet

Chassis Design Fundamental (AC)

- Chassis Design Fundamental Introduction (AC)

- Chassis Fundamental Overview

- Chassis Parts

- Chassis Design Fundamentals

- Creating Structural Darts

- Creating Flanges

- Frame Rail

- Crossmember Bracket

- Body Mount Bracket

Suspension and Steering Fundamentals (AC)

- Suspension and Steering Fundamentals Introduction

- Suspension and Steering Fundamentals Overview

- Suspension and Steering Parts and Operation Function

Evaluating the Part (AC)

- Evaluating the Part Introduction (AC)

- Evaluation Tools

- Face Analysis – Slope

Motion and FEA

- Motion and FEA Introduction

- Motion and FEA Overview

- Definition of Motion Application (AC)

- Mechanism and Motion Specific Terminology

- Motion Symbols

- Practical Uses of Motion

Scenario Environment

- Introduction – Scenario Environment

- Scenario Navigator

- Scenario Navigator Operations

- Master Model Dimension

- Materials

Motion Application Overview

- Introduction – Application Overview

- Motion Objects Overview

- Basic Articulation

- Motion Preferences

- Automatic Mating Condition Mapping

- Automatic Mating Condition Mapping – Using

- Listing Motion Connections

- Exporting an ADAMS Input File

Links and Markers

- Introduction – Links and Markers

- Link

- Link Creation

- Link Editing

- Link Information

- Marker Creation

- Marker Editing

- Marker Information

- Smart Point Creation

- Link Wireframe

Joints, Couplers, and Constraints

- Introduction – Joints

- Joints Overview

- Common Joint Parameters

- Revolute

- Slider

- Function Editor

- Joint Solids

- Universal

- Spherical

- Cylindrical

- Screw

- Planar

- Fixed

- Point on Curve

- Curve on Curve

- Rack and Pinion

- Gear

- Cable

- Joint Wireframe

- Joint Information

Post Processing

- Introduction – Post Processing

- Articulating the Mechanism

- Quick Drag

- Packaging Options

- Packaging Options – Measure

- Packaging Options – Trace

- Packaging Options – Interference

- Animation

- Spreadsheet Run

- Spreadsheet Run – Using

- Suspension Spreadsheet

- Graphs

- Graphing

- Graphing Jack

- Load Transfer

Finite Element Analysis

Fundamentals of Finite Element Analysis (FEA) – Introduction

FEA Overview

Strength of Materials

Structures Introduction

- Structures – Introduction

- Structures

- Structures – General Procedures

Creating a Scenario

- Creating a Scenario – Introduction

- Structures Manager

- Scenario Environments

- Scenario Environment- Defining

- Scenario1

Meshing Requirements

- Meshing Requirements – Introduction

- Meshing Requirements- Intended Use of Model

- Element Types

- Element Size and Count

- Material Type and Properties

Model Preparation

- Model Preparation – Introduction

- Midsurface

- Midsurface Creation Using Face Pairs

- Midsurface Creation Using Offset

- Midsurface Creation – User Defined

- Suppressing Features

- Feature Creation and Editing in Structures

- Idealize

- Mesh Mating Condition

- Master Model Dimension

- Model Variation Project

Loads

- Loads – Introduction

- Load Conditions

- Creating Loads

- Fatigue Load Variation

- Loads Project

Boundary Conditions

- Boundary Conditions – Introduction

- Boundary Conditions

- Boundary Conditions- Applying

- Boundary Conditions Project

Mesh Creation

- Mesh Creation – Introduction

- Automatic Meshing

- 3D Tetrahedral Mesh

- 3D Swept Mesh

- 2D Mesh- Creating

- 2D Mesh- Editing

- Mesh Checks for 2D Elements

- 1D Mesh- Creating

- 1D Element Section

- 1D Mesh- Creating Weld Elements

- Edge to Face Connection

- 1D Mesh Project

- Mesh Attributes

- Material Properties Project

- Rigid Connections Project

Quality Checks

- Quality Checks – Introduction

- Comprehensive

- Element Shapes

- Element Outlines

- Nodes

- 2D Element Normal

- Check 2D Mesh Project

- Check 3D Mesh Project

Solver

- Perform the Analysis – Introduction

- Nastran Solver Overview

- Linear Statics Plus Analysis

- Linear Analysis Solid Project

- Linear Analysis Shell Project

- Linear Static Axisymmetric Analysis

- Linear Buckling Analysis

- Normal Modes Analysis

- Crossmember Normal Modes Project

- Thermal Analysis

- Fatigue Analysis

Post Processor

- Postprocessor – Introduction

- Type

- Fringes

- Post Processor Project

- Identify

- Animation

- Display

- Animation Project

- View

- Auxiliary Scenario

- Crossmember Multiple Scenarios Project

- Hard Copy

- Quit

Automotive Essentials Training- NX-Unigraphics

Course Contents

Certification and Automotive Essentials Overview (AE)

- Automotive Essentials Diploma Overview Introduction

- Overview and Qualifications

- Automotive Essentials Overview

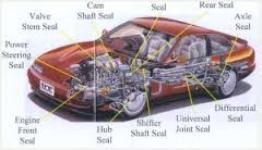

- Vehicle Systems

Drafting Workshop (AE)

- Drafting Workshop Introduction

- Drafting Overview

- Creating Views 1

- Creating Views 2

- View Preferences Project

- View Dependent Edits

- Drafting Style

- Tabular Note

- Parts List

- Drafting Workshop Task 1

- Drafting Workshop Task 2

Assembly Workshop (AE)

- Assemblies Workshop Introduction

- Assembly Design

- Chassis Assembly

Assembly Cloning (AE)

- Assembly Cloning Introduction

- Assembly Cloning Overview

- Cloning Assemblies

- Editing Existing Assemblies

Interpart Expressions (AE)

- Interpart Expressions Introduction

- Interpart Expressions

- Interpart Expressions – Creating and Editing

- Interpart Expressions- Using Expression Options

- Links

System-Based Modeling Overview (AE)

- System-based Modeling Overview Introduction

- System-Based Modeling Overview

- Applications

- Update Settings

- Geometry Linker

- Geometry – Creating

- Geometry – Editing

- Geometry – Management

- Information

- Simple System-based Modeling

System-Based Modeling Best Practices (AE)

- System-Based Modeling Best Practices Introduction

- System-Based Modeling Best Practices

- Design In Context

- In-Process Models

- Control Structures

- Modeling Errors

- Delayed Errors

- Circular References

- File Management

Component Filters (AE)

- Component Filters Introduction

- Filters and Zones

- Zone Creation

- Filters – Using with Load Options

- Scripts- Defining

- Filters and Zones – Best Practices

- Compressor Task 1

- Compressor Task 2

- Compressor Task 3

Representations (AE)

- Representations Introduction

- Representations

- Representations – Creating

- Assembly Hidden Line Removal

- Product Outline

- Product Outline – Defining

Product Data Management (AE)

- Product Data Management Introduction

- PDM Overview

- PDM Terminology

- PDM in the Automotive Industry

- PDM Data Storage

- PDM Workflow

- PDM Goals

- PDM Systems – Analysis and Comparison

- PDM Vehicle Configuration

Part File Standards (AE)

- Part File Standards Introduction

- Part File Standards Advantages

- CAD Standards – Setting

- Saving and Deleting Views

- Visualization

- Custom Views

- Layers

- Layer Category

- Object Display Preferences

- Visualization Preferences – Visual

- Visualization Preferences – Color Palette

- Visualization Preferences – Color Settings

- Properties – Part Attribute

Toolbars (AE)

- Toolbars Introduction

- Toolbars

- Toolbar Docking

- Toggle Toolbars

- User Tools

Resource Bar (AE)

- Resource Bar Introduction (SAE)

- Resource Bar

- Resource Bar Usage

- Palette Creation

- Resource Bar – Part Creation Using Templates

- Visualization Templates

- Drawing Template

- Navigator Properties

- Navigator Configuration

- Preparing a Seed File

Function of Part (AE)

- Function of Part Introduction

- Surface Complexity

- Dimensional Tolerances

- Design Time Versus Cost

- Stress Analysis

- Heat Treatments

Planning the Model (AE)

- Planning the Model Introduction

- Laying Out the Model

- Organizing the Model

- Beginning the Basic Model

- Smart Modeling Techniques

Electrical Systems Fundamentals (AE)

- Electrical Systems Fundamentals Introduction

- Electrical Routing

- Electrical Routing Terminology

Electrical Design Process (AE)

- Electrical Systems Fundamentals Introduction

- Basic Electrical Routing Procedure

- Qualifying Components

- Qualify Non-Electrical Components

- Qualifying Electrical Components

- Qualify Part – Clip

- Qualify Part – Connector

- Place Part Description

- Routing Paths – Creating

- Subdivide Segment

- Delete Path

- Logical Data and Physical Data

- Component List – Importing

- Connection List – Importing

- Filter Files – Importing

- Electrical Components – Manually Assign Unique IDs

- Create Terminals – Component List

- Components – Assign and Unassign

- Unmodel Terminals

- Routing and Unrouting Wires

- Routing Wires – Automatically

- Routing Wires – Manually

- Unrouting Wires

- Stock Offset Points – Creating

- Stock Offset Point – Point Method

- Creating Logical Associations

- Overstock

- Assigning Overstock

- Reports

- Reports – Accessing

Design for Manufacturing (AE)

- Design for Manufacturing Introduction

- Manufacturing Overview

- Machining Operations

- Remember the Tool

Industrial Processes and Materials (AE)

- Industrial Processes and Materials Introduction

- Automotive Materials and Processes

- Forging Overview

- Casting Overview

- Machining Operations Overview

- Sheet Metal Stamping/Hydroforming Overview

- Design for Manufacturing and Assembly

- Design for Specific Manufacturing Processes

Design for Manufacturing Modeling Methods (AE)

- Design for Manufacturing Modeling Methods Introduction

- Hub Forging

- Air Conditioner Compressor Bracket – Engine Mount

- Air Conditioner Compressor Bracket – Compressor Mount

- Air Conditioner Compressor Bracket – Machining

- Brake Module Bracket

Weldments (AE)

- Weldments Introduction

- Weldments Overview

- Modeling Weldments

- Weldments Using Promote

- Weldments Using Wave Geometry Linker

Tolerances (AE)

- Tolerances Introduction

- Tolerances Overview

- Tolerances in Design

- Tolerance Stacks

- Tolerance Stack Procedure

- Tolerance Allocation

- Managing Tolerances

Geometric Dimensioning and Tolerancing (AE)

- GD&T Introduction

- GD&T Overview

- GD&T Concepts

- GD&T Rules

- Datums

- Geometric Tolerances Types

- Form Tolerances

- Position Tolerances

- Profile Tolerances

- Virtual Condition

- Tolerance Stacks with GD&T

Sheet Metal Basics (AE)

- Sheet Metal Basics Introduction

- Sheet Metal Overview

- Sheet Metal Processes

- Sheet Metal Design Rules

- Sheet Metal Design

- Common Shapes

Sheet Metal Standards (AE)

- Sheet Metal Standards Introduction

- Parameter Standards

- Sheet Metal Preferences

- Global Parameters

- Checking Standards

- Standards File

Flanges (AE)

- Flanges Introduction

- Flange Creation

- Flange Restrictions

- Drill Press Task 4

- Enclosure Corner

- Bend Creation

- Flange Creation – Inset

- Door Task 1

- Bolt Task 1

- Profile Flange

- General Flange

- General Flange Creation – Parameters

- General Flange Creation – Build to Sections

- General Flange Creation – Build to Faces

- General Flange Creation – Punch Vector

Sheet Metal Features (AE)

- Sheet Metal Features Introduction

- Form/Unform

- Unbend/Rebend

- Direction Vector Definition for Sheet Metal Features

- Hole Creation – Sheet Metal

- Slot Creation – Sheet Metal

- Slot Formation

- Converting Form Features to Sheet Metal Features

- Door Task 2

- Cutout

- Relief

- Bead

- Punch

- Solid Punch

- Sheet Metal Features

- Bolt Task 2

- Door Task 3

- Edge Rip

- Corner

- Bracket

- Bracket

- Multibend Bracket

- Multibend Bracket Creation

- Strain

- MetaForm

Part in Process (AE)

- Part in Process Introduction

- Part In Process

- Part In Process – Using

Flat Patterns (AE)

- Flat Patterns Introduction

- Flat Pattern Preferences

- Flat Pattern Annotation Preferences

- Flat Patterns

- Flat Pattern Creation

- Flat Pattern Annotation

- Cutting Edges

Sheet Metal Assemblies and Drawings (AE)

- Sheet Metal Assemblies and Drawings Introduction

- Flat Patterns in Assemblies

- Flat Pattern Drawings

- Flat Pattern Drawing

- Flat Pattern Assembly

Automotive Interior Trim Training- NX-Unigraphics

Course Contents

Automotive Interior Trim

- Automotive Interior Trim Diploma Introduction

- Automotive Interior Trim Overview

- Styled Parts in Automotive Interior Trim

- Assemblies and Parametric Linking

Injection Molding (AIT)

- Injection Molding Introduction

- Injection Molding

- Mold Halves

- Wall Thickness

- Draft

- Flow

- Undercuts

- Openings

- Materials

- Material Selection

- Plastic Part Design CAD Process

Common Features (AIT)

- Common Features Introduction

- Ribs

- Snaps

- Living Hinges

Mold Design for Automotive Parts (AIT)

- Mold Design for Automotive Parts Introduction

- Mold Design for Automotive Parts Overview

- Designing Parts for Strength

- Designing Parts for Temperature

- Plastic Parts and Chemicals

Secondary Operations (AIT)

- Secondary Operations Introduction

- Machining

- Shielding

- Coatings

- Decorating

Preparing the Model (AIT)

- Preparing the Model Introduction

- Tool Considerations

- Scaling a Body

- Translation File Types

- Translating the Data

- Translators

- Translating Files

- Importing IGES, STEP, DXF and DWG Files

- Exporting IGES, STEP, DXF and DWG Files

- Heal Geometry

- Solid Creation

Draft (AIT)

- Draft Introduction

- Part Draft using Taper

- Taper

- Taper Creation – Faces

- Taper Creation – From Edges

- True Draft Taper

- Taper Creation – Tangent to Faces

- Taper Creation – Split Line

- Taper Editing

- Body Taper

Thin-Walled Bodies (AIT)

- Thin-Walled Bodies Introduction

- Thin-walled Bodies

- Hollow

- Hollow Creation – Face

- Hollow Creation – Region

- Hollow Creation – Body

- Hollow Editing

- Offset Face Creation

- Offset Face Editing

- Bosses and Cores

User Defined Features (AIT)

- User-Defined Features Introduction

- User Defined Features Overview

- User Defined Features – Advantages

- User Defined Feature – Configuring Libraries

- User Defined Feature – Creating Features with the Wizard

- Screw Boss UDF Creation

- User Defined Features – Inserting

- User Defined Features – Editing

- User Defined Features – Redefining

- Snap

- Screw Boss UDF Attach

Parting Lines (AIT)

- Parting Lines Introduction

- Parting Lines

- Offset

- Offset Curve Editing

- Project

- Projected Points and Curves Editing

- Combined Projection

- Combined Projection Editing

- Intersect

- Intersection Curve Editing

- Section

- Removing Associative Curve Parameters

- Subdivide Face

Surface Creation Using Strings (AIT)

- Surface Creation Using Strings Introduction

- Free Form Features

- Section String Selection

- Bounded Planes Creation

- Bounded Planes Editing

- Alignment Methods

- Simple Construction Method

- Through Curve Bodies Creation

- Through Curve Bodies Editing

- Through Curve Mesh Bodies

- Through Curve Mesh Bodies Creation

- Through Curve Mesh Bodies Editing

- Swept Bodies Creation Using One Guide String

- Swept Bodies Creation Using Multiple Guide Strings

- Swept Feature Editing

- Automotive Keyfob Task 1

- Automotive Keyfob Task 2

- Automotive Keyfob Task 3

Free Form Best Practices (AIT)

- Free Form Best Practices Introduction

- Free Form Feature Considerations

- Avoiding Problems in Free Form Features

- How to Fix Imperfect Faces Bodies

- Finding the Balance

Offset Surface Operations (AIT)

- Offset Surface Operations Introduction

- Offset Free Form Feature

- Offset Surface Editing

Feature Operations (AIT)

- Feature Operations Introduction

- Feature Operations

- Extract

- Extracting Associative Curves

- Extracting Faces

- Extracting a Region

- Extracting a Body

- Extract Feature Editing

- Trim Body

- Trim Body Editing

- Sewing Best Practices

- Sew

- Patch

Evaluating Plastic Parts (AIT)

- Evaluating Plastic Parts Introduction

- Evaluation Tools

- Object Information

- Point Information

- Distance Between Objects

- Angle Between Objects

- Minimum Radius

- Part Information

- Face Analysis – Slope

- Deviation Analysis

- Examine Geometry

- How to Fix Imperfect Faces Bodies

- Hollow Problems

Face and Soft Blends (AIT)

- Faces and Soft Blends Introduction

- Blend Creation – Face

- Blend Editing – Face

- Face Blend Edit

- Blend Creation – Soft

- Blend Editing – Soft

Editing Unparametric Sheet Bodies (AIT)

- Editing Unparametric Sheet Bodies Introduction

- Isoparametric Trim Divide

- Degree

- Stiffness

- Change Edge

- Boundary

- Reverse Normal

- Base Plate

Plastic Part Assemblies (AIT)

- Plastic Part Assemblies Introduction

- Plastic Part Assemblies

- Press Fits

- Snaps

- Snap Design

- Fasteners

- Bonding

- Ultrasonic Welding

- Other Welding Techniques

- Staking

Appendix (AIT)

- Appendix Introduction

- Glossary

- Common Materials

- Design Rules

- Resources

Automotive Powertrain Training- NX

Course Contents

Automotive Powertrain introduction

- Automotive Powertrain Diploma Introduction (AP)

- Automotive Powertrain Diploma Overview (AP)

Design Principles (AP)

- Design Principles Introduction

- Design Planning Stage

- Starting the CAD Model (AP)

- Modeling Best Practices (AP)

- Creation Methodology (AP)

- Settings and Rule (AP)

Design Modeling Techniques (AP)

- Design Modeling Techniques Introduction (AP)

- Modeling Creation Methods (AP)

- Clean Edge Modeling Technique (AP)

- Clean Edge Approach Bracket

- Shaping the Part (AP)

Draft (AP)

- Draft Introduction

- Part Draft using Taper

- Taper

- Taper Creation – Faces

- Taper Creation – From Edges

- Taper Creation – Tangent to Faces

- Taper Creation – Split Line

- Taper Editing

Parting Line Development (AP)

- Parting Lines Introduction

- Parting Lines Overview (PC)

- Project

- Projected Points and Curves Editing

- Intersect

- Intersection Curve Editing

- Section

- Subdivide Face

Thin – Walled Bodies (AP)

- Thin-walled Bodies Introduction (AP)

- Thin-walled Bodies (AP)

- Hollow

- Hollow Creation – Face

- Extract

- Extracting Faces

- Extracting a Region

- Thicken Sheet

Engine Fundamentals (AP)

- Powertrain Fundamentals Introduction

- Engine Fundamental Overview

- Engine Parts

- Engine Operation Function

- Engine Design Fundamentals

- Valve Cover Rough Shape

- Creating Flanges

- Casting Features

- Piston Design

- Pipe Design

- Tension Casting

Transmission Fundamentals (AP)

- Transmission Fundamentals Introduction

- Transmission Fundamental Overview

- Transmission Parts and Operation Function

HVAC Fundamentals (AP)

- HVAC Fundamentals Introduction

- HVAC Fundamentals Overview

- HVAC Parts and Operation Function

- HVAC Design Fundamentals

Evaluating the Part (AP)

- Evaluating the Part Introduction (AP)

- Evaluation Tools

- Face Analysis – Slope

Motion and FEA

- Motion and FEA Introduction

- Motion and FEA Overview

- Definition of Motion Application (AP)

- Mechanism and Motion Specific Terminology

- Motion Symbols

- Practical Uses of Motion

Scenario Environment

- Introduction – Scenario Environment

- Scenario Navigator

- Scenario Navigator Operations

- Master Model Dimension

- Materials

Motion Application Overview

- Introduction – Application Overview

- Motion Objects Overview

- Basic Articulation

- Motion Preferences

- Automatic Mating Condition Mapping

- Automatic Mating Condition Mapping – Using

- Listing Motion Connections

- Exporting an ADAMS Input File

Links and Markers

- Introduction – Links and Markers

- Link

- Link Creation

- Link Editing

- Link Information

- Marker Creation

- Marker Editing

- Marker Information

- Smart Point Creation

- Link Wireframe

Joints, Couplers, and Constraints

- Introduction – Joints

- Joints Overview

- Common Joint Parameters

- Revolute

- Slider

- Function Editor

- Joint Solids

- Universal

- Spherical

- Cylindrical

- Screw

- Planar

- Fixed

- Point on Curve

- Curve on Curve

- Rack and Pinion

- Gear

- Cable

- Joint Wireframe

- Joint Information

Post Processing

- Introduction – Post Processing

- Articulating the Mechanism

- Quick Drag

- Packaging Options

- Packaging Options – Measure

- Packaging Options – Trace

- Packaging Options – Interference

- Animation

- Spreadsheet Run

- Spreadsheet Run – Using

- Suspension Spreadsheet

- Graphs

- Graphing

- Graphing Jack

- Load Transfer

Finite Element Analysis

- Fundamentals of Finite Element Analysis (FEA) – Introduction

- FEA Overview

- Strength of Materials

Structures Introduction

- Structures – Introduction

- Structures

- Structures – General Procedures

Creating a Scenario

- Creating a Scenario – Introduction

- Structures Manager

- Scenario Environments

- Scenario Environment- Defining

- Scenario1

Meshing Requirements

- Meshing Requirements – Introduction

- Meshing Requirements- Intended Use of Model

- Element Types

- Element Size and Count

- Material Type and Properties

Model Preparation

- Model Preparation – Introduction

- Midsurface

- Midsurface Creation Using Face Pairs

- Midsurface Creation Using Offset

- Midsurface Creation – User Defined

- Suppressing Features

- Feature Creation and Editing in Structures

- Idealize

- Mesh Mating Condition

- Master Model Dimension

- Model Variation Project

Loads

- Loads – Introduction

- Load Conditions

- Creating Loads

- Fatigue Load Variation

- Loads Project

Boundary Conditions

- Boundary Conditions – Introduction

- Boundary Conditions

- Boundary Conditions- Applying

- Boundary Conditions Project

Mesh Creation

- Mesh Creation – Introduction

- Automatic Meshing

- 3D Tetrahedral Mesh

- 3D Swept Mesh

- 2D Mesh- Creating

- 2D Mesh- Editing

- Mesh Checks for 2D Elements

- 1D Mesh- Creating

- 1D Element Section

- 1D Mesh- Creating Weld Elements

- Edge to Face Connection

- 1D Mesh Project

- Mesh Attributes

- Material Properties Project

- Rigid Connections Project

Quality Checks

- Quality Checks – Introduction

- Comprehensive

- Element Shapes

- Element Outlines

- Nodes

- 2D Element Normal

- Check 2D Mesh Project

- Check 3D Mesh Project

Solver

- Perform the Analysis – Introduction

- Nastran Solver Overview

- Linear Statics Plus Analysis

- Linear Analysis Solid Project

- Linear Analysis Shell Project

- Linear Static Axisymmetric Analysis

- Linear Buckling Analysis

- Normal Modes Analysis

- Crossmember Normal Modes Project

- Thermal Analysis

- Fatigue Analysis

Post Processor

- Postprocessor – Introduction

- Type

- Fringes

- Post Processor Project

- Identify

- Animation

- Display

- Animation Project

- View

- Auxiliary Scenario

- Crossmember Multiple Scenarios Project

- Hard Copy

- Quit

Automotive Structures Training- NX-Unigraphics

Automotive Structures (AS)

Course Contents

- Automotive Structures Diploma Introduction

- Automotive Structures Diploma Overview

Body in White Design Principles (AS)

- Body in White Design Principles Introduction

- BIW Design Overview

- BIW Design Process

- Parts in Body in White Design

- BIW – Planning Stage

- BIW – Starting the CAD Model

Die Design and Tooling (AS)

- Die Design and Tooling Introduction

- Die Design Overview

- Die Design Structure

- Die Design Advantages and Disadvantages

- Die Tooling Design

Body in White Design Modeling (AS)

- Body in White Introduction

- Model Creation Methods

- BIW – Clean Edge Modeling Technique

- BIW – Clean Edge Application

- BIW – Shaping the Part Overview

- BIW – Rough Shape Envelope Creation

- BIW – Front Hinge Pillar Envelope

- BIW – Shaping the Part

- BIW – Stamped Depressions

- BIW – Complex Depression Creation Techniques

- BIW – Complex Depressions on Contoured Surface

- BIW – Fuel Filler Depression

- BIW – Front Hinge Pillar Depressions

- BIW – Flanges for Stamped Sheet Metal

- BIW – Flange Creation

- BIW – Offset Flange

- BIW – Door Inner Flange

- BIW – Front Hinge Pillar Flanges

- BIW – Beads

- BIW – Bead Creation

- BIW – Front Hinge Pillar Bead

- Dart Creation

- BIW – Dart Creation Using Tool Solids

- BIW – Front Hinge Pillar Completion

- BIW – Roof Bow Development